DAKAR 2026

VAN ORTON

ABOUT FPT

DAKAR 2026

VAN ORTON

ABOUT FPT

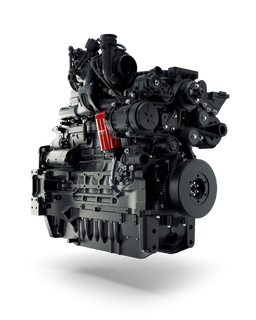

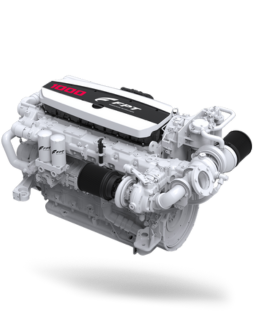

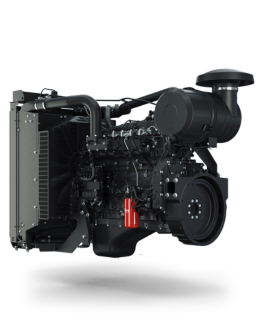

Innovation powers our solutions. Explore the range.

A great network

at your side.

You can count on our large network of distributors and

service points in more than 100 countries worldwide.

Always

in motion

Find out more about the latest projects,

events, and updates.

events, and updates.

Press Releases

News & Events

CARE & ASSISTANCE

Our support service is active 24/7. Select

a country to find out your zone helpline.

080 026 603 78