ORIGINAL REMAN

- HOME/

- CUSTOMER SERVICE/

- original reman

Regeneration: the sustainable choice.

The Original Reman world is about people and values. We tell through those who work in it, the world of remanufacturing, and the commitment to sustainability and reuse of resources, goal zero waste. The steps in this process are complex and delicate, so they are carried out with meticulous precision by experienced technicians. Watch the video and learn more about the world of Original Reman.

DOWNLOAD BROCHURE

Discover the main benefits:

Cost-efficiency ensuring same or better performance

Low total cost of ownership

Best-in-class 2-year warranty to ensure your peace of mind

No compromise on quality

Sustainable process for a circular economy

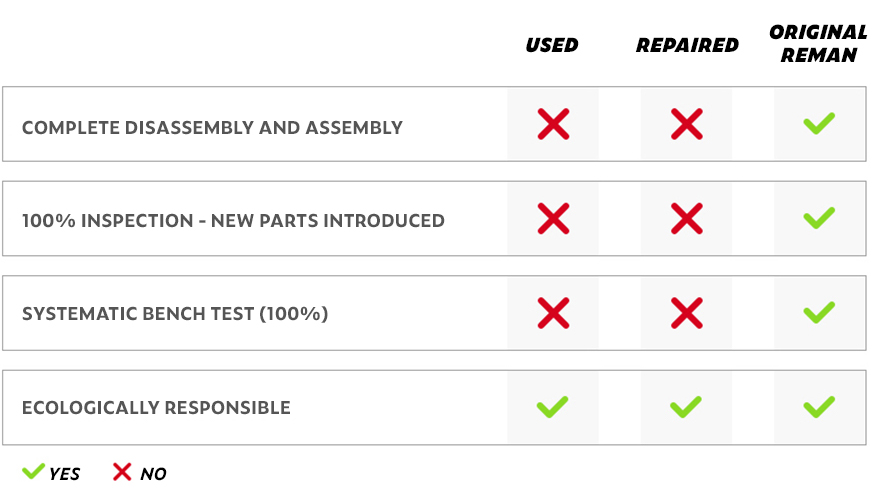

You gain the same quality.

Remanufacturing starts with the complete analysis and disassemblying of the engine. Each component is then carefully inspected and thoroughly cleaned using diverse mechanical and chemical methods. In the assembly stage, highly skilled technicians integrate new components to ensure every single customer gets all the most recent improvements and to guarantee the full certification of the original regeneration. That is the process behind Original Reman.

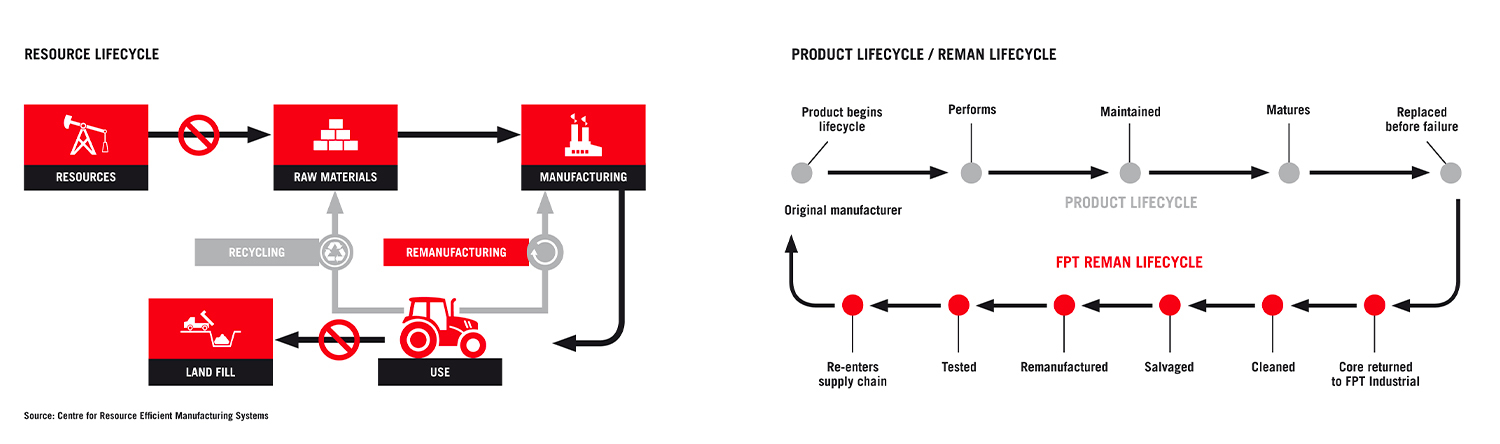

THE FLOW OF SUSTAINABILITY

By adhering to the ideal circular flow of the remanufacturing process, Original Reman helps to save the environment, keeping used components out of landfills and offering cost-effective parts that are environmentally sustainable.

Do you want to know more?

CARE & ASSISTANCE

Our support service is active 24/7. Select

a country to find out your zone helpline.

080 026 603 78