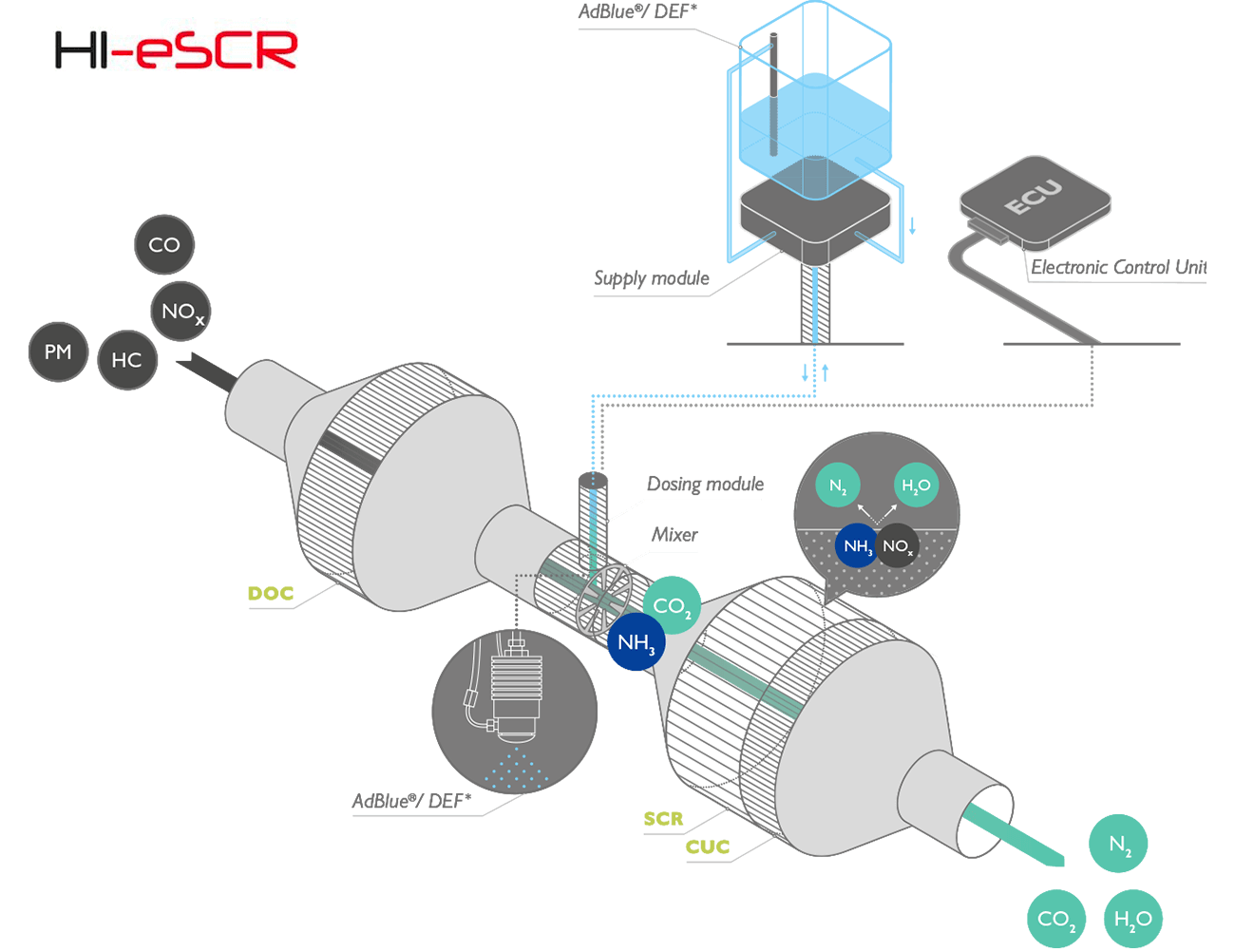

EURO VI

Legend

- PM Particulate Matter

- HC Unburnt Hydrocarbons

- NOx Nitrogen Oxides

- CO Carbon Monoxide

- N2 Nitrogen

- CO2 Carbon Dioxide

- H2O Water

*AdBlue® / DEF = CO(NH2)2 + H2O

FPT engines for on-road applications achieve Euro VI emission levels with our exclusive, patented HI-eSCR system.

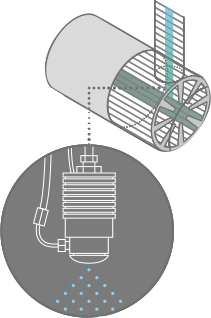

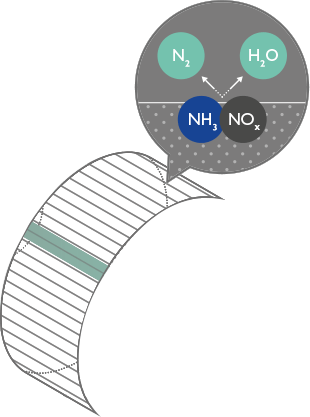

Thanks to continuous R&D, we have enhanced SCR technology (Selective Catalyst Reduction), that transforms NOx into nitrogen (N2) and water (H2O) by injecting Urea in the exhaust pipe. This allowed us to develop a no-EGR solution, based on optimized combustion and very high NOx-conversion efficiency (95-98% versus 80-85% of competitors’ average).

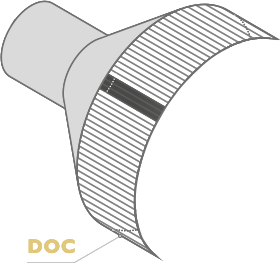

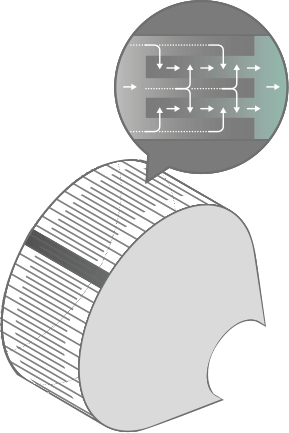

Patented HI-eSCR features include an exclusive Urea dosing control system (based on a network of integrated sensors that monitor any excess in NOx and Ammonia) and a thermally-insulated high-turbulence mixer, that allow homogeneous urea hydrolysis and full emission compliance.

NOx abatement is provided by SCR only. This ensures more simplicity, no additional encumbrance, less energy dispersion, and easier servicing. Optimized temperature in the combustion chamber reduces fuel consumption and particulate generation, so lowering emissions without efficiency loss. Excellent transient response also maximizes productivity. No forced/parked regeneration avoids downtime.